Installation and OH&S — BraceBolt™

![]() Before installation, the following conditions must be met:

Before installation, the following conditions must be met:

Refer to bracing plan on site and bracing requirements and a minimum concrete strength of 20MPa must be achieved.

Anchors spacing to have a minimum distance of 250mm all around and a minimum edge distance 250mm

Use safety equipment eye protection, ear protection and face mask.

Flanged Safety BoltBrace Base Detail

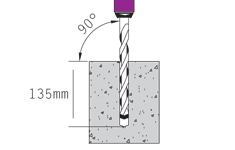

DRILL

DRILL

DRILL

DRILL

Drill

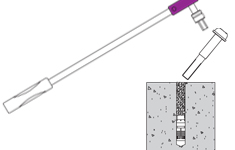

Drill a diamiter 20mm hole, perpendicular (90°) to the face and to a minimum depth of 135mm.

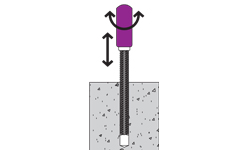

CLEAN

CLEAN

CLEAN

CLEAN

Clean

Remove dust and debris from inside of hole and around the lip to obtain a flat, clean surface for the brace foot.

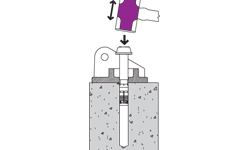

Installation

Installation

Installation

Installation

Installation

Place brace foot over drilled hole. Insert BraceBolt through brace foot and into drilled hole. Drive home BraceBolt with hammer.

Click here for more >>

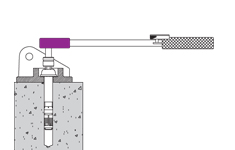

Torque Settings

Torque Settings

Torque Settings

Torque Settings

Torque Settings

Use the rated tagout lockout 14mm Hex drive socket and using tension wench or load control equipment apply a torque of 150Nm to set.

Removal

Removal

Removal

Removal

Removal

Use the rated tagout lockout 14mm hex drive socket to remove BraceBolt. Fill hole with grout and level off.

OHS Warning

OHS Warning

OHS Warning

OHS Warning

OHS Warning

Before any braces are removed the Concrete Element must be checked for fixture into the building structure and the site control officer has signed off.